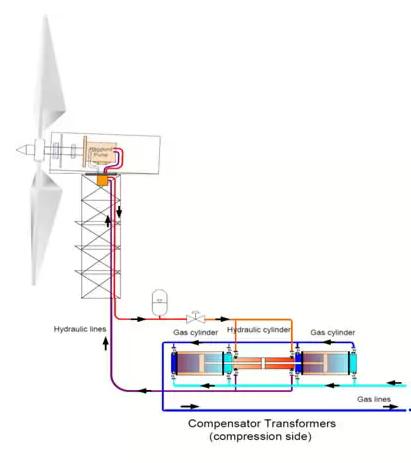

A canadian company called Lancaster Windsystems is building a new type of wind turbine. As we suggested before it uses the mechanical power from the wind to compress gas that drives a turbine downstream. Instead of a big geared generator in top of the turbine it has a hydraulic pump. The hydraulic pressure is used to compress gas downstream.

The first part of the system shows the hydraulic lines that compress gas that gets stored in storage tanks. Compression generates a lot of heat ususally, which means energy is lost. When the gas is used it expands and it absorbs a lot of heat, so that in some cases fuel is needed to heat the gas. This is a drawback of storage systems using compressed gas. The advantage of such systems is their low cost. They may even be integrated in the wind turbine pilons as some battery and hydrogen storage systems have been.

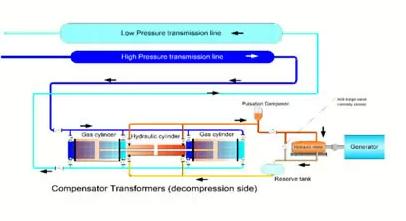

Downstream the stored gas is used to drive a regular gas turbine. This design is cheaper and possibly more efficient simply because the technology used is so common. Vertical turbines generators need to handle different wind speeds when converting the rotation of the blades into energy. As the Lancaster system buffers the wind energy in the gas tanks it can always run the generator at the optimal speed, even taking demand into account.

The reason this blog tries to draw attention to alternative uses of wind beside direct driving of generators, is that the cost are lower and the applications are hard to patent. It is impossible to patent a vertical turbine driving a hydraulic pump after several centuries of use of mechanical wind power for pumpin water, sawing, pressing, hammering you name it. This is important because we need as much renewable energy as soon as possible. In some cases like the ‘Dutch Rainmaker’ it seems investors stall the sale of a final product by making it much more expensive (700.000 instead of 10.000), this type of stalling strategy may also happen to this system. But if you like the idea, nobody keeps you from starting a project exactly like it.