Blow the image of a russion patent of 2006 on a horizontal axis wind heating device. Wind turbines that generate heat are game changers, they can be very cheap. The low tech challenge of generating heat from any torque source makes it hard to patent. Yet google ‘Joule machine’ and you’ll find that a 2006 paper on a vertical axis wind to heat generator is no longer available. With storms picking up due to climate change cold areas of our planet can do with some heat. We plan to build a demo this week of a VAWT wind to heat generator. If you want to be part of this process send us some cash 😉 We need about 3000 Euro for a full scale demo within a month. All contributors will be mentioned and share in 20% of the project revenues.

Earlier we shown our own design, apple’s ripoff and the study from singapore from 2006 that layed out how to calculate the power and yield of a vertical axis wind to heat generator. You could find that study by googling "Joule machine", but it seems it has been pulled.

Cave drawing of Vestas patented wind driven heat exchanger

A more interesting party to dive into this area is Vestas Wind Systems A/S, a major player in wind turbines. Yet Vestas patented a wind powered heat exchanger. Their [patent focusses on the heat exchanger, I guess it’s about driving fluid or gas through the exchanger where the friction will cause heat to be produced.

"The present invention relates to a wind turbine generator comprising a heat exchanger and a first and second cooling circuit for cooling a heat-generating source in the wind turbine generator, e.g. a gear-box or a generator. The invention also relates to heat exchanger for general purposes and a method for cooling a heat-generating source with such a heat exchanger."

In Holland the same thing happened as mentioned before, a company called Dutchrainmaker developed a wind powered cooling device, used to condense water out of the air. Of course at the same time it’s a heating device, because cooling always goes hand in hand with heating.

This technology can ruin the day of many gas companies. Where it’s windy in winter you don’t need gas anymore. Combined with heat storage f.i. using ammonia (split at high temperature and recombined using a cathalyst when the heat is needed) it may allow for all kinds of economic activity without to much cost. The technology could not be simpler. This may be a good way to fend of it’s implementation by the fossil interested/dependent banking system.

Random pulled cost decomposition of a wind turbine (source)

To build it yourself it’s easier to make a vertical version. This type of turbine is more stabile, costs less and is less noisy than horizontal axis turbines. The cost, vertical or horizontal, are a fraction of the present turbine cost. It requires no generator, gear box, control electronics, power connector, transformers etc. At the same time the yield in terms of heat is higher than when using electricity, although conversion of torque into electrical power is very efficient. With heat the losses (usually heat) are added wins. The cost of the mechanics of heat generation in a wind turbine can be low, as there are standard products like compressors that can do that job. Maybe the cost can be one third cheaper, and less complicated as well.

Wind heat generators don’t need gearboxes, or to turn at high speed.

To build a vertical version the designs are widely available, and most patents have expired. The biggest challenge is self starting, which a horizontal axis windturbine does at all times (unless it’s wrongly directed). The basic calculations of power and yield can be made using the Singapore paper. Some numbers on the heat generator are shown below.

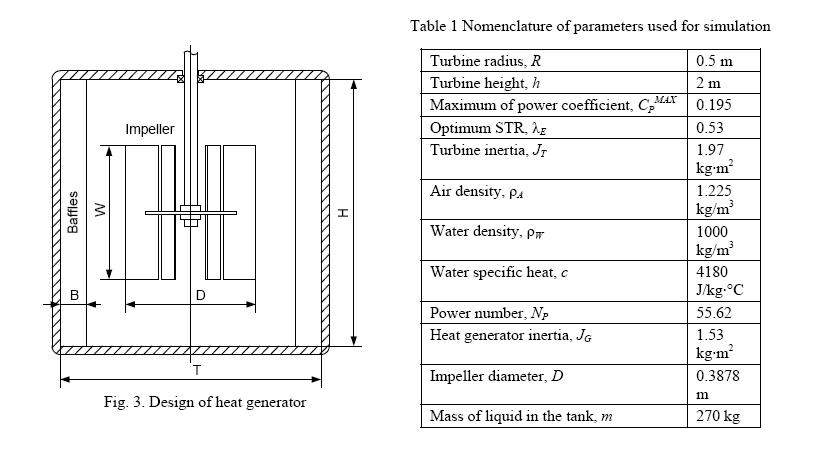

The image shows the water tank in which the water is stirred by an impeller. The tank must also have breaks mounted to the side to slow the water down. The total friction of the water churning around is converted into heat, if it isn’t the axle of the impeller will speed up which reduces the power absorbed by the wind turbine. In this case the device has a radius of .5 meter, a height of 2 meter. The watertank is 270 liter.

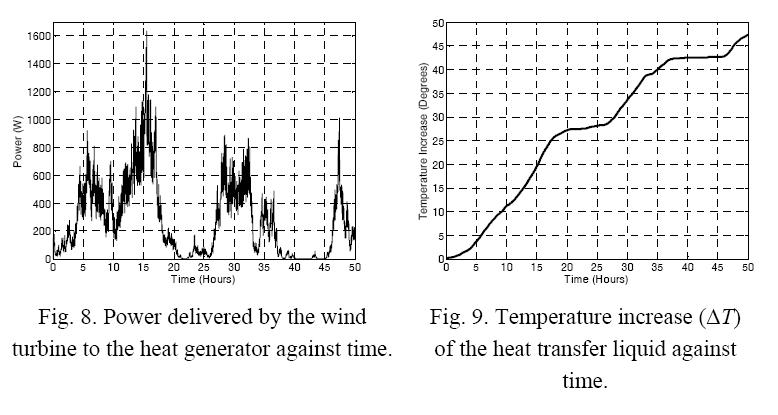

The effect of stirring water can be observed in the abover simulation results. They show that over time, with the input of wind energy the temperature of the water rises. This hinges on good insulation, which should not be a problem. The temperature rises up to 50 degrees, but can go higher up to the boiling point. Apple proposes to drive a steam turbine with the steam, so in that case we would be talking super heated steam of up to 500 degrees. Of course these temperatures can only be reached under pressure. For home heating this is not necessary.

The variability makes it hard to confirm the output, but we can take this model and calculate that at the average speed of 7,5 m/s this would be between 50 and 290 Watts (ok wide berth). The power needed to heat 270 liter of water to 47 degrees (assuming no losses). The energy needed to heat 1 Kilogram of water 1 degree Celsius is 4184 Joule, so the power to heat 270 liter 47 degrees is 53044200 joules. The average output has to be about 294 Watt, which is higher than the assumed power in the wind. The model will probably have calculated no losses.

A wind driven heat pump can turn 1 kW of wind energy into 4 kW of heat

Of course the stirring tank method of wind to heat conversion could be complemented with a wind driven heat pump. There is a big difference, because a heat pump creates a temperature differential, while the tank shown above always heats up. The heatpump method means you can reach higher temperatures quicker, provided you have a reserve of heat you can ‘upgrade’. Then the effecto of 1 kW wind energy input can be 4 kW heat, according to the COP of the heatpump.

This type of device can be build with light resources, so sails instead of hard rotors. It comes down to the torque that can be transferred to the axle. Enfin.. wordt vervolgd..