To travel requires energy, we are used to that, because we are used to moving our flexible and unstabile body over uneven ground step by step. But in reality moving does not require energy. If we wheren’t in Earths and Suns gravity well any effort (expending energy) to move would set us moving on a new course for (practically) ever. If you make a very stiff vehicle, like a train on rails, you can eliminate a lot of the loss cars and trucks experience as they move over bumpy roads on airtires. Trainwheels, car, truckwheels and suspensions get hot as they absorb energy meant to move the vehicle through the other major obstacle : The air.

The resistance of the air increases rapidly as you speed up. As you go faster the air that is in the way has to accelerate faster out of the way. It also gets compressed, and it sticks to your vehicle so there is drag. So a fast vehicle needs to help the air out of the way, move as little as possible and be as slippery as possible. This determines the usual shapes of ‘aerodynamic’ vehicles.

If you remove the air form the equation moving requires a lot less energy. The only energy it will require is the resistance as you fight gravity as well as the cost of changing direction (against the rails or road) which can be very low if your vehicle is very stiff. This is what inspired Elon Musk to propose the Hyperloop.

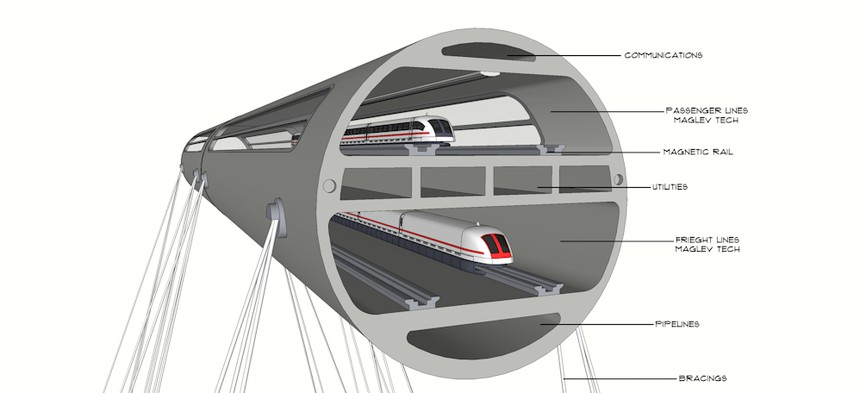

The idea of Hyperloop is to create a vacuum, through which a vehicle can move without air resistance. This requires airtight tubes and vehicles, a lot like planes (all large passenger planes maintain an internal pressure and oxygen level that is higher than that of the air they fly through). Until now this has been achieved using steel or concrete tubes.

Most concept are of an electrically driven pod for a small number of passengers so that there is a lot of flexibility in using the actual vacuum tubes. To us this seems a harder approach to start with. Why not have services at specific times, just like airlines. Universities working on concepts like this usually embelish and certainly the TU Delft is deep in bed with fossil, so they sell H2 cars and will slow down competition for airlines through endless research.

One of the scary aspects of this mode of transportation is that you are sealed stuck inside a vehicle for the entire time of any hyperloop leg. Nothing can go wrong or you are likely to suffocate in the tube. Fire on board is a major concern. New batteries are much safer than the well known lithium ion batteries. They also burn against oxygen when you puncture them outside, but which is not available in a hyperloop tube. New batteries (Lithium titanate f.i.) don’t have this problem. We assume no fire hazard battery tech will be used in any case. There is an answer to the vacuum risk as well, as you will read below.

We assume any trip would involve travel from normal pressure tube sections to lower pressure tube sections (full vacuum may not be necessary). The lowest pressure sections should be as straight and long as possible. Our vehicle would be the maximum size that can still follow the curve of the tubes. Tubes would have to be extremely tough. Legs would be 350 km long with 50 km sections, the less the better.

The current test track hyperloop tubes are made of steel. This may have been the choice because it is easy to open then up or cut through them if a test vehicle gets stuck. This however is not the safest option if the tube is going to be left outside (where people can interfere). In some artist impressions you see the tube on high pilons, this is because people who mean harm can’t get to it easily that way (and it can move above build areas).

A great way to use Hyperloop, if it delivers on its promise to allow travel at 800 km/h, is to build tubes along the European and Mediterranian coasts, under water. They could either float from anchors of be suspended form surface pontoons. Then you would have very little problems to build the routes fast. Conceptual work has been done on a transatlantic maglev connection based on a similar idea. Still, laying 5000 km of underwater concrete tubes seems a titanic undertaking, estimated cost : $12 Trillion. The hyperloop seems easier

Lets consider the options of laying tubes along coasts under water, some underwater trajectories, assuming no stops..

- 1600 km track from Rotterdam to Bilbao, 2 hours

- 750 km track betwen Barcelona and Genua, 1 hour

- 1700 km track Venice to Athens, 2,5 hours

- 750 km Marseille Algiers, 1 hour

- 350 km Marseille Barcelona, 30 mins

- 350 km Barcelona, Valencia, 30 mins

- 2500 km Quatar to Mumbai, 3,5 hours

These are absolutely enormous distances and one has to assume a vehicle that can power itself for 4 hours straight, as we said it would have to be large, we don’t see any problem there. To deal with any accident where the vehicle has to stop or gets stuck one can imagine a safety system where two big baloons are inflated in front and behind the vehicle, sticking to the outside of the tube, to block the vacuum (a bit like a stent). These could operate on compressed air carried along. Any rescue vehicle could come in and do the same so a pressurized section of tube can be created to move people to safety.

So we assume a featureless tunnel and propulsion to be integrated in the tube lining or vehicle. Then the question becomes : How do we make these tubes sections quickly. One option is to make them out of laminated glass. Thin glass can be bend and vacuum laminated and achieve incredible strength while also being flexible. Thin glass can be fabricated on large rolls and then used to laminate tube sections almost in situ.

Of course glass bend for the diameter of about 4 meters the tube will be won’t have to be so thin. New ways of processing glass can make it incredibly strong. A continues process could mean seamless tubes.

Still it would be possible to have emergency/maintenance stations every 50 km or so. Glass could make it possible to use static leviation, where the glass and the vehicle have the same charge and work like static bearings. Using glass this way could even make it feasible to have windows in the hyperloop pod, so people can see themselves move under the surface of the ocean at mind blowing speeds, now that’s a future we like!

Another innovative way of using glass to realize the hyperloop involves using sand directly, where it is found. This would be a great way to build the tube sections in the desert areas, to cross the Sahara, acros Saudi Arabia. Sand can be melted using sunlight and turned into tube sections. These would be opague and much heavier and tube sections would have to be connected. The production of the tube sections could be done in parallel by multiple solar powered installations along the route. One of the challenges to deal with climate change is that our transition itself needs to have the lowest possible emissions.

There is a great need for speed in the development of emissions free logistics but also building technology. There is a need for new techniques to build roads, buildings etc. because using concrete is quite CO2 intensive. The fossil industry is still pushing for its own interests, and always mentions cost and efficiency as criteria for good ideas. Both are irrelevant if we move into the ‘roboeconomy’ which is the fully renewable powered automated economy. Because cost is a function of resource scarcity, and renewable energy can be made very abundant. Efficiency is also related to resource scarcity. We don’t need 99% efficient wind turbines if we have a ton of them, nor does anyone reject solar panels because they are only 15% efficient. What matters is that we can enjoy the products and services we desire.