Silver prices are rising due to US money printing, so called Quantitative Easing combined with the growing awareness that banks don’t know themselves what their real position is. Silver is claimed to be essential for solar PV (solar panels) and does play a role in the manufacture of high reflectance mirrors for Concentrated Solar Power (CSP).

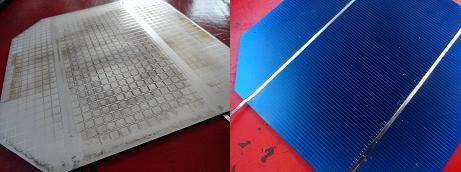

Old silver backed cell, you can see the conductive path is very thin on the front.

In solar panels it functions to transport the electrons from the solar cell back and front. Solar cells are like a dam (semiconductor), where the wind (light) blows water (electrons) up onto a ledge (through the semi conducting barrier), in most cells the back will be positive (too little electrons) under light, and the front negative (to much electrons). To utilize this imbalance one has to take the electrons from the front and allow them to do usefull work as they reach the back. Whereas the backside can be covered with silver, creating a large low resistance conductor for electrons to travel through, on the front of a cell the amount must be minimal to not block light from actually producing current in the cell. Because the less metal on the front of the cell, the more power it can generate, there are special designs for so called back-contact cells.

Heraeus, a silver bar manufacturer, advertises with front side silve paste.

Silver is used to reduce resistance. It is printed to the front of the cells, where resistance has the biggest performance cost. Another place where it can reduce resistance and increase durability is as part of the solder paste on the ribbons. So called tabbing ribbon connects cells (visible in the top picture), and cell strings, having optimal thickness and width to have the least resistance. These ribbons are usually made of copper, because that allows flexibility and prevents damage to fragile cells as they are soldered together.

The ribbon is often covered in silver containing solder (as you see above), and this is the second use of silver in PV panels. The amount of silver in solder may help but it is not clear how much of a difference it makes. Strictly speaking the solder does not have to contain any silver.

If you remove the silver from the ribbon solder it is possible to make entire solar panels without the use of silver. The alternative is using aluminum and copper, which are less conductive, but can produce acceptable results. SCHOTT Solar AG produced a cell that had an output of 19,7%, so that’s a cell, not a panel. Inec and Kaneka also developed silver free cells achieving an output of 21%. This is comparable to normal cells.

">">

Imec’s cell is special because it manages to combine multiple cells in one, in a way that is similar to a series of cells. But the point is that aluminium and copper can be used instead of silver, and copper is realtively abundant.

But another point that can be made is that although silver means more output for the cells, a bit less output doesn’t have to be a problem. It is only in a world where you constantly need to be the best because money was invested and land is expensive so you want the maximum output from your solar farm. This drive to maximize efficiency is mainly a result of scarcity of resources, pospone production and gain patents. This in turn is a result of a fossil fuel driven top heavy market.

Roboeconomic perspective

In a world where renewables are the primary source of productivity one would not need to be the best constantly, just be sufficient. So if your solar panel produces a bit less power but you have enough of them to make your life or the life in your community prosper nobody cares whether you used silver, copper or aluminum. Also if the methods you use to manufacture are all driven by renewables, for instance a geothermally powered aluminum refinery like the ones we see in Iceland, then the cost may be much lower than if you insist on using fossil fuels and silver. We clearly see that maximizing output is unnecessary because there are thin film and organic/synthetic dye solar cells with lower standard outputs that are still viable for the market.

We are likely to see a bigger differentiation in solar panel technology, namely CIS panels (Copper Indium Selenium) and thin film at a lower cost as renewables start to be used to manufacture them. In the end we wont depend on silver, but more on the expansion and modernization of the renewable energy source manufacturing pool, something we should see as the key to a prosperous future.